At this location, we work with the latest generation of high-performance flexographic printing presses that are characterised by particularly high speed and accuracy for instance.

We can realize up to 10 colors per print run.

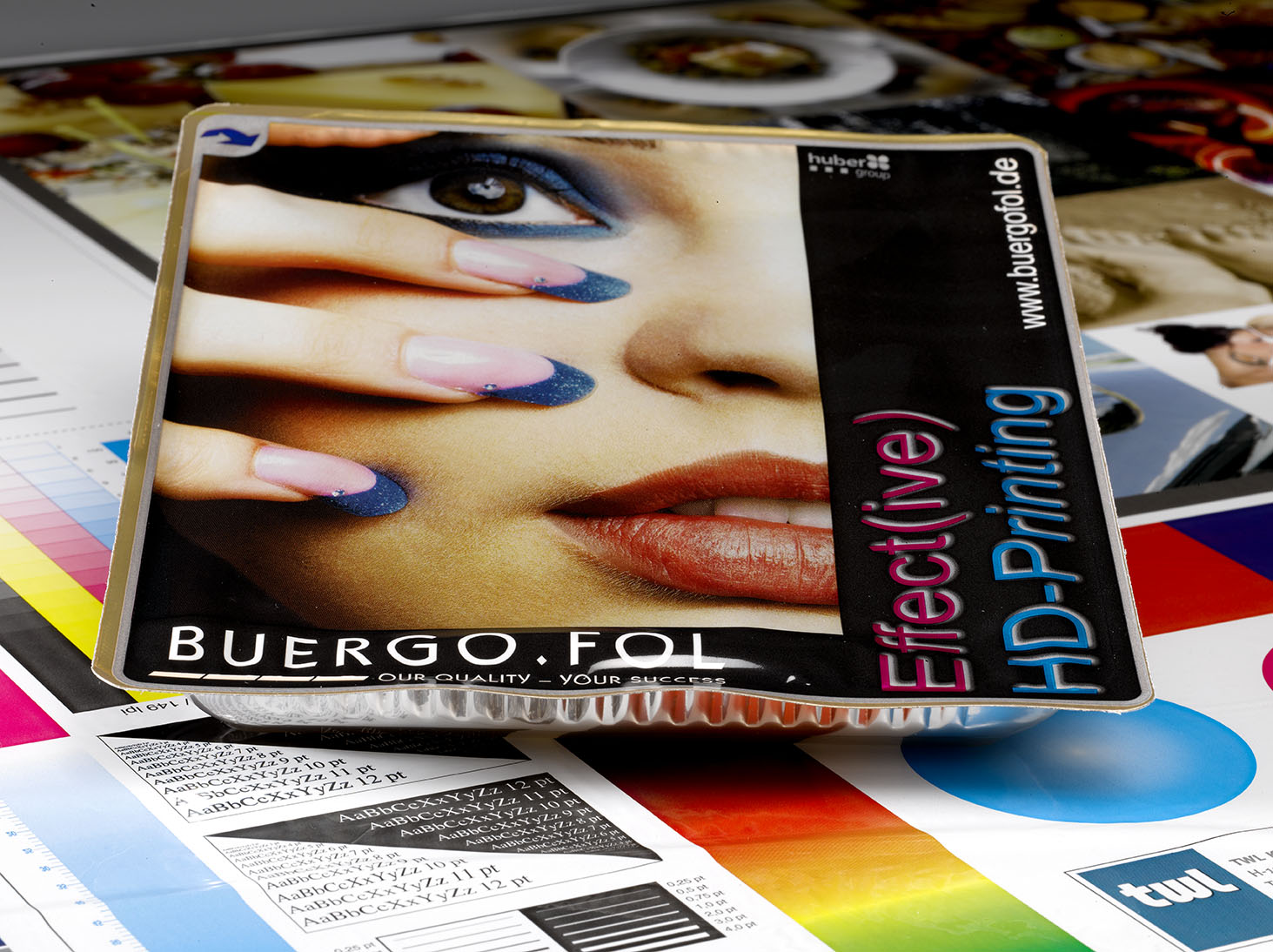

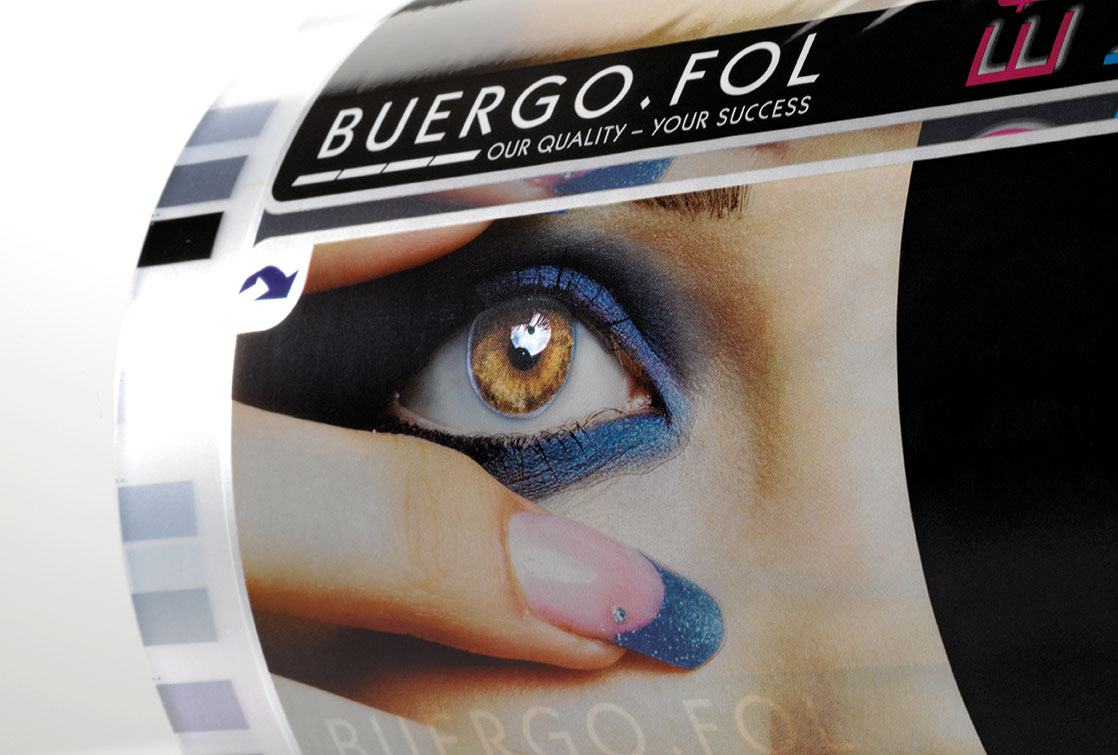

The possibility of partial orders in reverse printing to achieve haptic and visual effects sets us apart from many competitors.

Our metrologically based printing standard guarantees predictably the best printing results under advanced production conditions.

The application of technical applications is also possible.

Flexible materials such as PE, PP, OPA, PET and BOPP are suitable as printing materials, but also rigid materials, e.g. rigid films such as A-PET.

We provide a way for effective product protection.

The printed packaging is uniquely designed through the use of effect pigments, technical coatings or individual coding in the printed image. This can be done, for example, on the lid film. This product protection is important because product piracy is now causing damage in the billions and counterfeiting in the food and medical sectors can even damage the health of consumers.

Click one of our contacts below to chat on WhatsApp